Lean Leadership – The Dance to the Rhythm of Challenge and Response

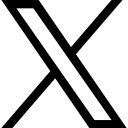

Leadership is the courageous and creative response to challenge. Lean leadership is no different.

Leadership is the courageous and creative response to challenge. Lean leadership is no different. No significant change happens in the absence of challenge. There is no Martin Luther King in the absence of racism; no Churchill absent fascism; and, no Lincoln absent slavery. One could argue that all progress is in the dance to the rhythm of challenge-and-response.

In business the challenge is different. It is the challenge of innovation – new technologies, new markets, and new economic conditions. There is no Henry Ford absent the challenge presented by the internal combustion engine; no Bill Gates absent the microprocessor; and no Mark Zuckerberg absent the internet. Lean leadership is the response to the challenge of innovative methods and the potential of human creativity. The task of the lean leader is to define the strategic challenge for his or her organization and present that challenge in a way that creates a response that results in significant change and continuous improvement.

It would be wonderful to believe that simply sharing knowledge of a better way would result in the adoption of that better way. If only we were rational beings. But after assisting dozens of companies with their efforts to institute a lean culture, it is very obvious that the success of those efforts is directly linked to the quality and constancy of lean leadership. Lean Leadership and Lean Culture require very specific actions on the part of leaders and I do not think those actions of been well articulated in previous books and articles. I have attempted to define these actions in my new course on Lean Leadership and Lean Culture and I want to summarize them here.

To Challenge and to Serve

Leaders define the mountain to be climbed, the worthy purpose that will motivate followers to sacrifice. They then recognize the task to serve the needs of their followers by enabling them, providing the tools, the guidance, the skills, the path toward success, and finally, celebrating that success. Challenging employees and then serving them may seem to be almost contradictory functions, but they are both necessary sides to the same coin.

The Challenge is Strategy

The challenge is strategy… it is where we are going and why we are going there, and it is only the leaders of the organization who can set that strategy and establish the challenge. It is the primary function of leadership in every organization, whether an army or an entrepreneurial start-up company. Too many leaders set their sights too low. They are too practical. They establish a target, a challenge, of improving operating efficiency by ten percent. Or, reducing cycle time by twenty percent. Do those goals inspire you? Do you seriously think they inspire employees to sacrifice for “the cause?” I doubt it. Because we are too often punished for the failure to achieve goals we reduce our vision to that which is easily understood and achieved. Toyota’s global vision states:

“Toyota will lead the way to the future of mobility, enriching lives around the world with the safest and most responsible ways of moving people.

Through our commitment to quality, constant innovation and respect for the planet, we aim to exceed expectations and be rewarded with a smile.”

That’s big! Toyota isn’t in the car business, they are in the mobility business, and their job is to enrich lives around the world! From that challenge may flow ten thousand more specific challenges, targets or goals, that lead to the fulfillment of the big vision. But, you must start with a motivating challenge that gives people dignity and purpose. That is the root cause of motivation and change.

Lean Leaders are “Servant Leaders”

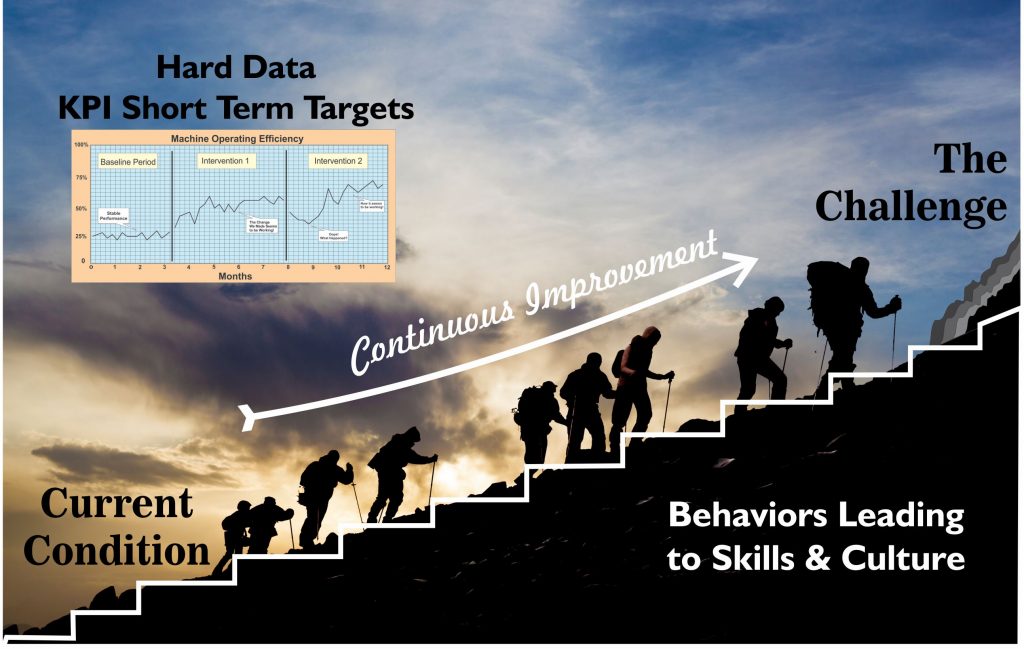

I have identified six specific functions of lean leaders, each of which are essential to implementing lean principles in an organization. Here is a quick overview of those six functions. (These are explained in some detail in my course.)

1. Develop External/Business Strategy

Business strategy is a response to external threats and opportunities, both employing and then developing internal capabilities. Lean leadership and culture is not divorced from business strategy, but is rather a means of developing the internal capabilities that will enable the organization to execute business strategy.

2. Develop Internal Culture Strategy

External strategy defines where we are going. Internal strategy defines what we need to get there. Strategy is only achieved if there is alignment of internal culture and capabilities to the strategy. Peter Drucker is reported to have said that “Culture eats strategy for breakfast.” The point is that you can’t achieve a business strategy if you don’t have the necessary culture and capabilities. The absence of this alignment creates friction, and friction is waste… not lean!

3. Lead System Design

Too many lean consultants think you can simply go into an organization and start doing PDCA problem solving at the first level and create a lean culture. This is too easy! Too often the barriers that create interruptions and waste in the process are determined at a higher level. They are both social and technical. They are the relationships with suppliers, the layout of the plant, the existence of warehouses and staffs. They are layers of management that suck decision up and rob employees of dignity and the ability to solve problems. In short, they are system problems that require design thinking! The lean leader recognizes the need for systems and structure to align with strategy and creates a process of redesign.

4. Be the Model

Leadership is modeling the behavior desired of others. If you have sat in a meeting of senior managers at Honda or Toyota, as I have, you would witness the practice of effective team management, problem-solving and consensus reaching. You would also witness leaders asking if they have “been on the spot” (the Gemba) to directly observe the work and listen to the “world’s greatest experts.” In other words, they are practicing Respect for People and Continuous Improvement, the two core principles of lean culture. Your ability to institute culture change is directly related to your ability to be a model of that culture.

5. Coach & Develop Others

A leader is a coach. A leader knows that his or her job is to develop the capacity of others. The greater the capacity of others the easier is the job of the leader. At Toyota every manager has a coach, an internal coach, a peer. I developed my course on Coaching Leaders for Continuous Improvement to aid in the development of this internal capacity. Continuous improvement is not only about the production line. It is about personal development, the desire to personally improve our own skills. This is the job of a coach and we need to develop a culture of coaching others, which is a form of service to others.

6. Motivation and Accountability

In our desire to develop a positive culture it may be easy to put aside the reality that it is the manager’s job to hold others accountable. Even in an environment of self-directed teams, the manager is responsible for assuring that those teams are accountable for performance. Toyota practices “Four-to-One” which is the practice of four positive comments to one negative. Research in the 1960’s by Dr. Ogden Lindsley demonstrated that the optimum learning environment sees more positive than negative interactions. The actual ratio he found was 3.57 to one. While the exact number is not important, it is important that we recognize that motivation to continuously improve must be reinforced positively.

Each of these six components of lean leadership deserve serious study and practice by the leader or manager wishing to implement lean management and culture. I have tried to aid that study with my Udemy course on Lean Leadership and Lean Culture.

Categories: : leadership, lean

Lawrence Miller Miller

Lawrence Miller Miller